"Servicing Everything Conveyors"

At SEC Business Group (SEC-BG), we deliver complete end-to-end conveyor support designed to maximise efficiency, extend equipment life, and reduce downtime. Our experienced team provides reliable, safe, and practical services that keep industries operating at full strength.

From component supply, installation and splicing to auditing and shutdown execution, we service everything conveyors — with the right plan, the right parts, and the right people.

Component Supply

At SEC-BG, we don’t just service conveyors — we supply the parts that keep them running. Our range includes rollers, pulleys, scrapers, lagging, skirts, and critical spares, all selected for durability and safety. With our consignment inventory systems, essential components are always available on-site, eliminating procurement delays and ensuring rapid response when you need it most.

Auditing & Inspections

Through comprehensive conveyor audits and inspections, we provide detailed reporting and actionable insights into system performance. Our team identifies potential risks before they escalate, helping clients plan ahead, optimise efficiency, and avoid costly failures. These audits form the backbone of a proactive approach to plant reliability.

Shutdown Planning & Execution

We deliver complete shutdown management, including labour, compliant tooling, and equipment. Our teams arrive fully prepared to execute shutdowns safely, efficiently, and on schedule. From detailed planning through to final reporting, SEC-BG ensures smooth project delivery that gets operations back online quickly and with confidence.

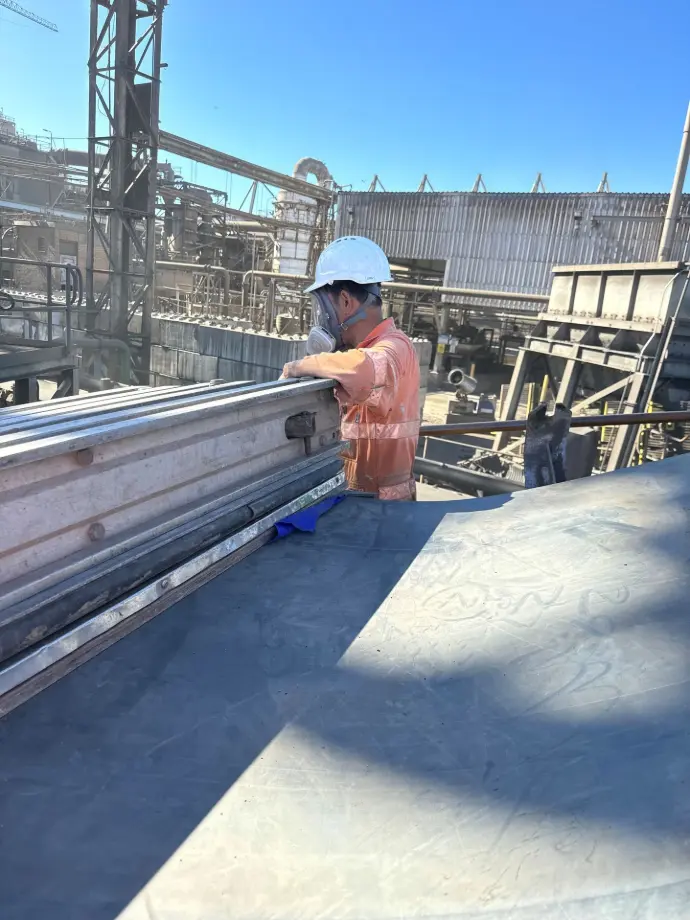

Skirt Adjustment & Replacement

Our skirt adjustment and replacement services are designed to contain material at transfer points, minimise airborne dust, and prevent costly clean-ups. By implementing effective skirting systems, we help maintain a cleaner worksite, protect equipment from unnecessary wear, and ensure your operation meets strict environmental and safety standards.

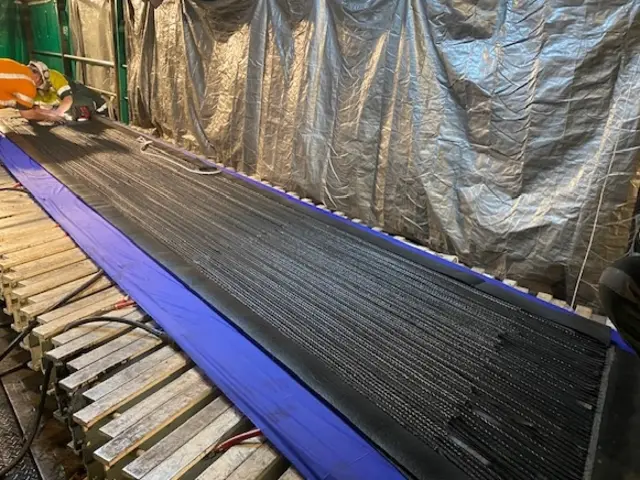

Belt Splicing

We perform both hot and cold belt splicing to exact industry specifications, guaranteeing durable, accurate joins that extend belt life. Whether planned as part of routine servicing or delivered under high-pressure shutdown conditions, our splicing services are carried out with speed, precision, and reliability.

Conveyor Installation & Maintenance

Installation and routine servicing to ensure maximum efficiency, safety, and reliability. We handle every stage of conveyor installation with precision — from initial setup and alignment through to full commissioning. Once installed, our team provides ongoing servicing tailored to the specific demands of your site. Regular maintenance not only ensures maximum efficiency and reliability but also reduces the risk of costly breakdowns and safety incidents.

Scraper Installation & Maintenance

Effective belt cleaning systems to prevent carry-back, protect equipment, and reduce hygiene costs. Carry-back can create serious inefficiencies — increasing wear on equipment, creating safety hazards, and driving up maintenance expenses. By reducing material build-up, our solutions help protect conveyor components, lower hygiene and clean-up costs, and improve overall site productivity.

Bucket Elevators

The supply and service of all componentry to service, maintain, and refurbish bucket elevators. Bucket elevators are critical to handling bulk materials efficiently, and their reliability depends on the quality of the components that drive them. We supply, service, and refurbish all essential bucket elevator componentry — from chains, buckets, and belts through to drive assemblies and wear parts. By combining premium parts with skilled maintenance, we ensure your elevators operate safely, smoothly, and with minimal downtime, even in the most demanding conditions.

Pulley, Idler & Frame Solutions

From manufacturing and refurbishing pulleys to supplying and replacing idlers and frames, we provide durable component solutions engineered for long-term performance. Every product is designed to handle heavy loads and tough conditions, reducing maintenance requirements and ensuring consistent reliability on site.

More Than Maintenance

At SEC Business Group, our work goes beyond routine conveyor servicing. We take a proactive approach that safeguards productivity, reduces unexpected failures, and extends the life of critical assets.

Through detailed audits, inspections, and preventative maintenance programs, we deliver insights that allow clients to anticipate challenges before they occur. By combining technical expertise with foresight, we minimise downtime, control costs, and keep operations running smoothly under pressure.

When it comes to shutdowns, we arrive fully prepared — with the right plan, the right parts, and the right people to get the job done efficiently and safely. It’s this commitment to preparation and performance that keeps Australia’s industries moving at their best.

See Our ProductsKeep Your Operation Moving

Get in touch to see how SEC-BG can support your site.